by Karthik K | Oct 5, 2018 | Project Updates

Earlier this year, EMJ completed an expansion at Ruby Falls, a tourist attraction in Lookout Mountain, Tenn., that boasts the nation’s largest public underground waterfall. Our team constructed a new lobby, retail space, pedestrian mall, and more next to the original,...

by Karthik K | Jan 26, 2018 | Employee News, In the news

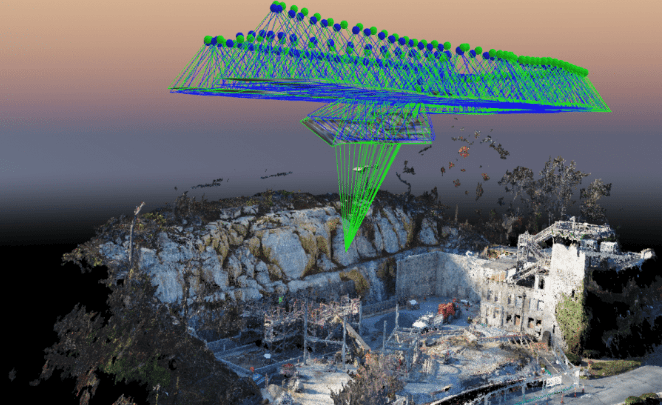

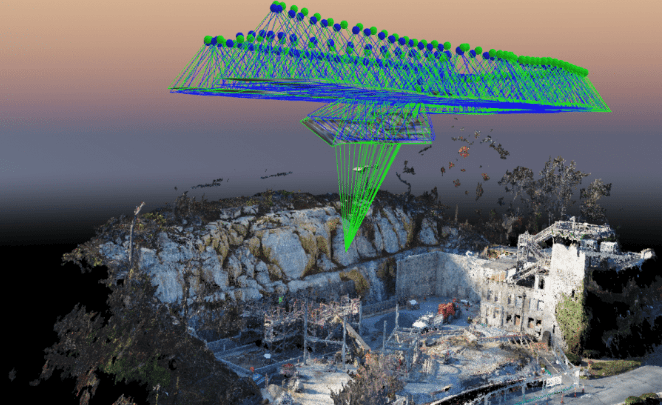

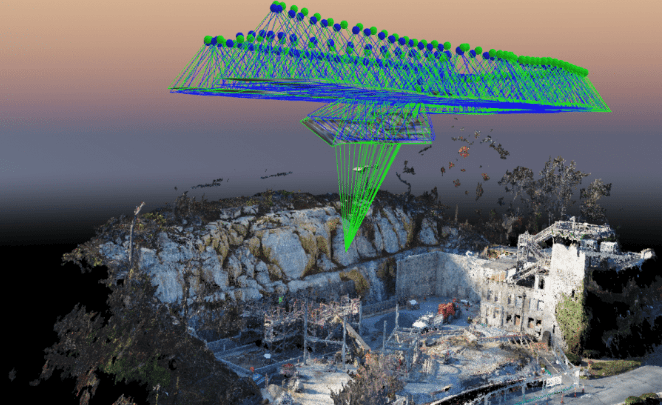

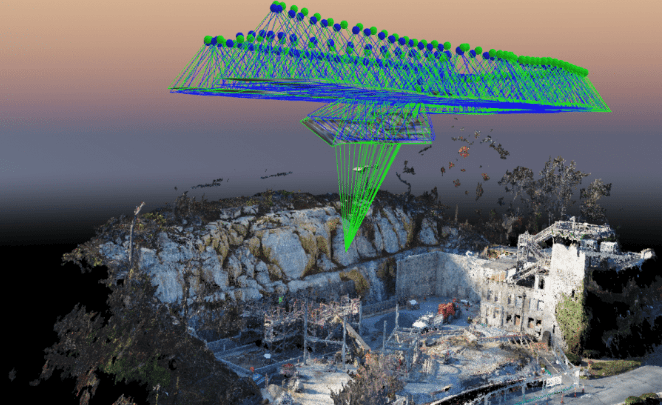

A site capture of Firestone in Opelika, Ala., offers measurements at 1-inch accuracy through use of survey control points. Construction of the Firestone store in Opelika, Ala., required a series of cut and fills before construction began. Wanting to ensure that...